UHF RFID for Material Tracking in Manufacturing

UHF RFID in Manufacturing

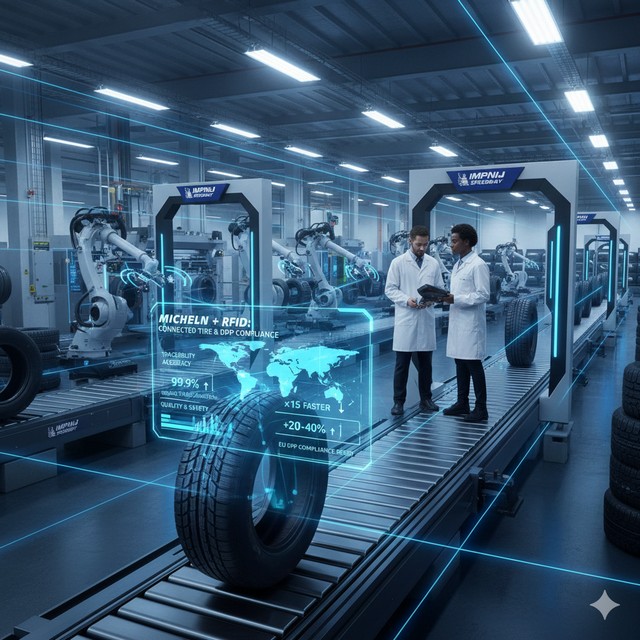

UHF RFID in manufacturing is used to automate inventory tracking, monitor material flows and increase operational visibility.

Unlike manual processes and barcode scanning, UHF RFID enables automatic identification of materials and products without line of sight, which is critical in high-speed production environments.

In real-world deployments, RFID tracks raw materials, work-in-progress and finished goods across all production stages, from receiving to shipping.

Industrial-grade UHF tags are used, designed to withstand mechanical stress, dirt and temperature variations, delivering read rates of 99% and above.

From a management perspective, RFID reduces labor effort, minimizes inventory errors and material losses, and improves production planning accuracy.

Accounting operations are accelerated by 3–7x, while inventory visibility reaches 98–99%.